Develop

Develop

HOTO bearing always pays attention to the investment in technology research and development based on the business philosophy of "people-oriented, rule of law, quality and continuous innovation". HOTO technology center has a national accreditation (CNAs) laboratory, a national recognized enterprise technology center, a national technological innovation demonstration enterprise and a postdoctoral research workstation.

HOTO technology center takes "hard research and leading technology" as the development strategic guidance, and attaches importance to the research and development of industry cutting-edge technologies and key technologies; We have actively implemented the strategy of technological innovation, achieved fruitful research results, and formed a core technology system with independent intellectual property rights. More than 800 new products are developed every year, and the research on rolling bearing vibration and noise, sealing, lubrication, long service life, calculation and analysis is at the domestic advanced level; It has made a large number of application achievements in the research and development of key bearing processes and core parts technology, and has mastered and owned a large number of core bearing manufacturing technologies. At present, it has the ability to research and develop various types of bearings within the range of inner diameter 1mm to outer diameter 10000mm, among which the low-noise silent bearings for industrial motors, long-life car gearbox and hub bearings, high-speed air flow spinning machine bearings and other core products have reached the international advanced level.

Corporate Culture

Corporate Culture

QUALITY POLICY QUALITY POLICY

With experienced high-end talent team and complete bearings Professional analysis and finite element analysis software, able to Systematize the mechanical, kinematic and dynamic properties of components Analysis and design.

OPERATING STRATEGY OPERATING STRATEGY

Professional research and development of special bearing steel, forming and heat treatment technology Bearing lubrication and sealing materials ensure long service life Impact resistance, heavy load, high and low temperature and other complex working conditions.

BUSINESS POLICY BUSINESS POLICY

Technical specifications for tests under various working conditions of various bearings Test equipment, test equipment development capability and test data Processing and analysis ability to provide strong support for customer product development Support.

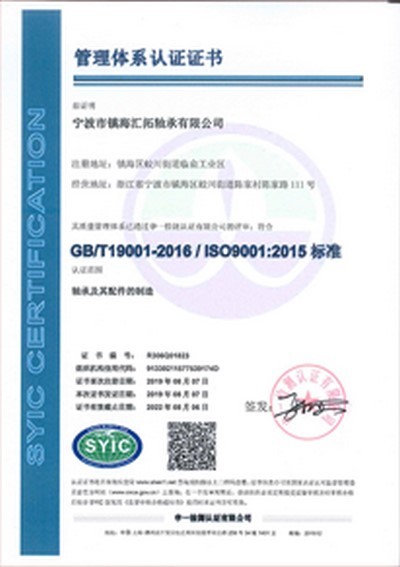

Qualification certificate